Your expert for plain bearings

Quality and experience for over 25 years

With more than 25 years of experience and a commitment to quality, we are your reliable partner for repairs and new production of plain bearings (dual-material) using proven processes such as centrifugal casting, gravity casting and deposition soldering.

Performance and flexibility

We machine plain bearings and turned parts up to a diameter of 1,000 mm and carry out all work steps in-house.

Reliability that convinces

Our experienced staff guarantees precision, adherence to deadlines, and short delivery times. Upon request, we can deliver personally within a 150-km radius.

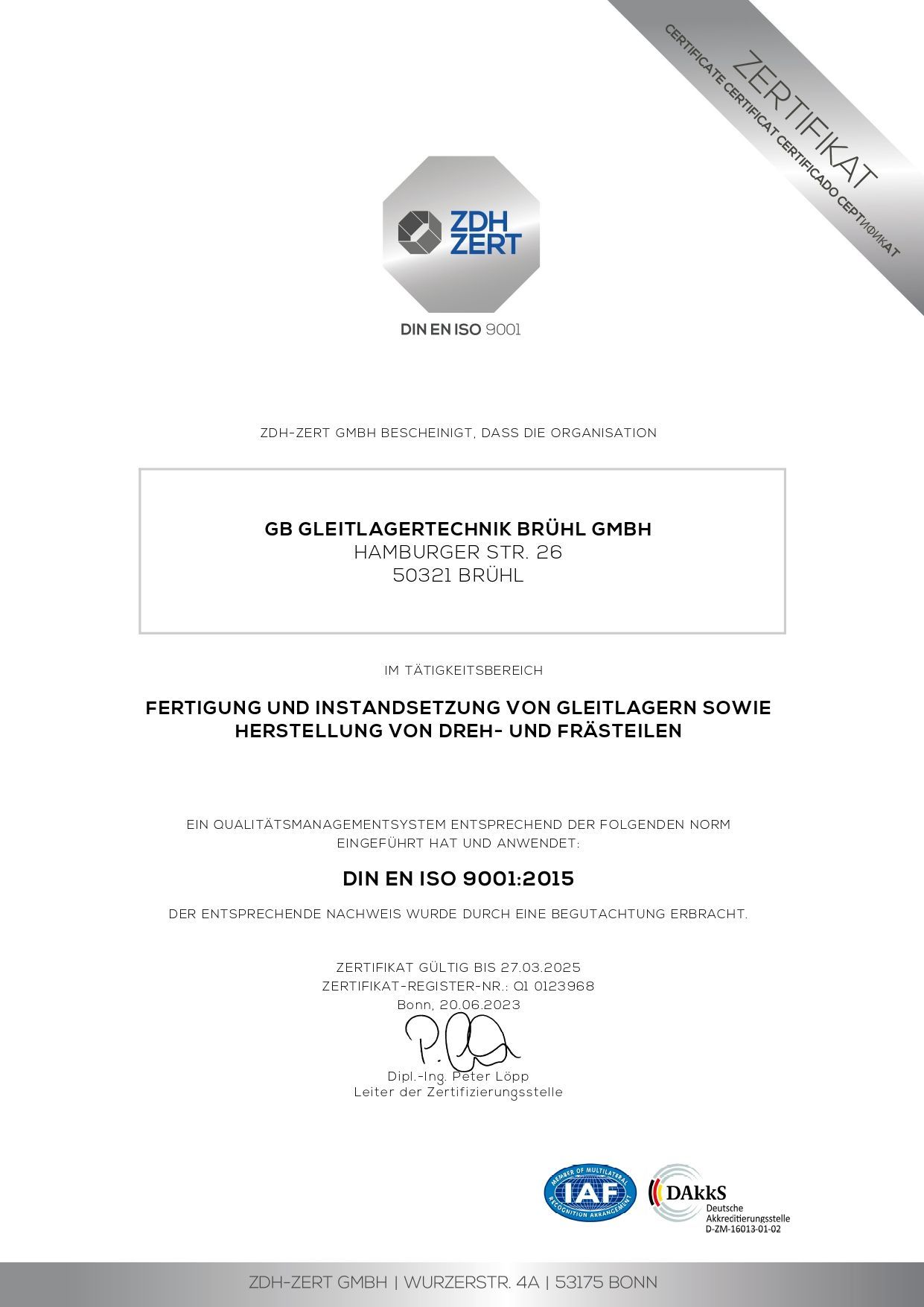

Quality made visible

All work is documented and documented with test reports. We also perform ultrasonic testing in accordance with DIN ISO 4386 on-site or in-house.

Your partner for the highest quality

Rely on our experience, flexibility and outstanding services – we are here for you!